Smart Mining Solution

Our Smart Mining Solution will make your mining site safer, greener and more productive with an installation of a cloud/AI-based management system.

Industry Trend

Mining industry is in dire need to resolve existing issues in order to increase productivity, lower cost and improve safety. A unified digital strategy is essential for achieving the goal. We offer the market with a turnkey, cloud based, E2E Smart Mining solution. With the help of 5G and AI, the entire mine site can be fully monitored and the on-site operation can be greatly improved and optimized. The adoption of our solution will help business decision making and simplify the effort in digital transformation for mining companies.

Xingtera’s smart mining solution for open pit provides a fully integrated system that monitors the entire mine site, including the inspections for materials in hopper, the speed of cargo/truck, smoking and fire, worker situation as well as the alert for the abnormal. The system is consistent of AI technologies, big data, on-prem cloud platform, and software and hardware ecosystem, enabling the smart collaboration of various devices, smart control and O&M of the mine-site operation.

Pain Points

Open Pit Mining is distinguished from other fields by its basic structure. It requires production in continuously changing environmental conditions due to the diversity of natural conditions and therefore contains multiple risks and operation inefficiencies from the production phase to final shipment. These issues might lead to undesirable situations, huge waste of resources and the amount of workplace accidents.

Solution Overview

Xingtera Smart Mining is a cloud based, E2E system. This solution will power your mining operation and business with 5G and multiple cutting-edge technologies.

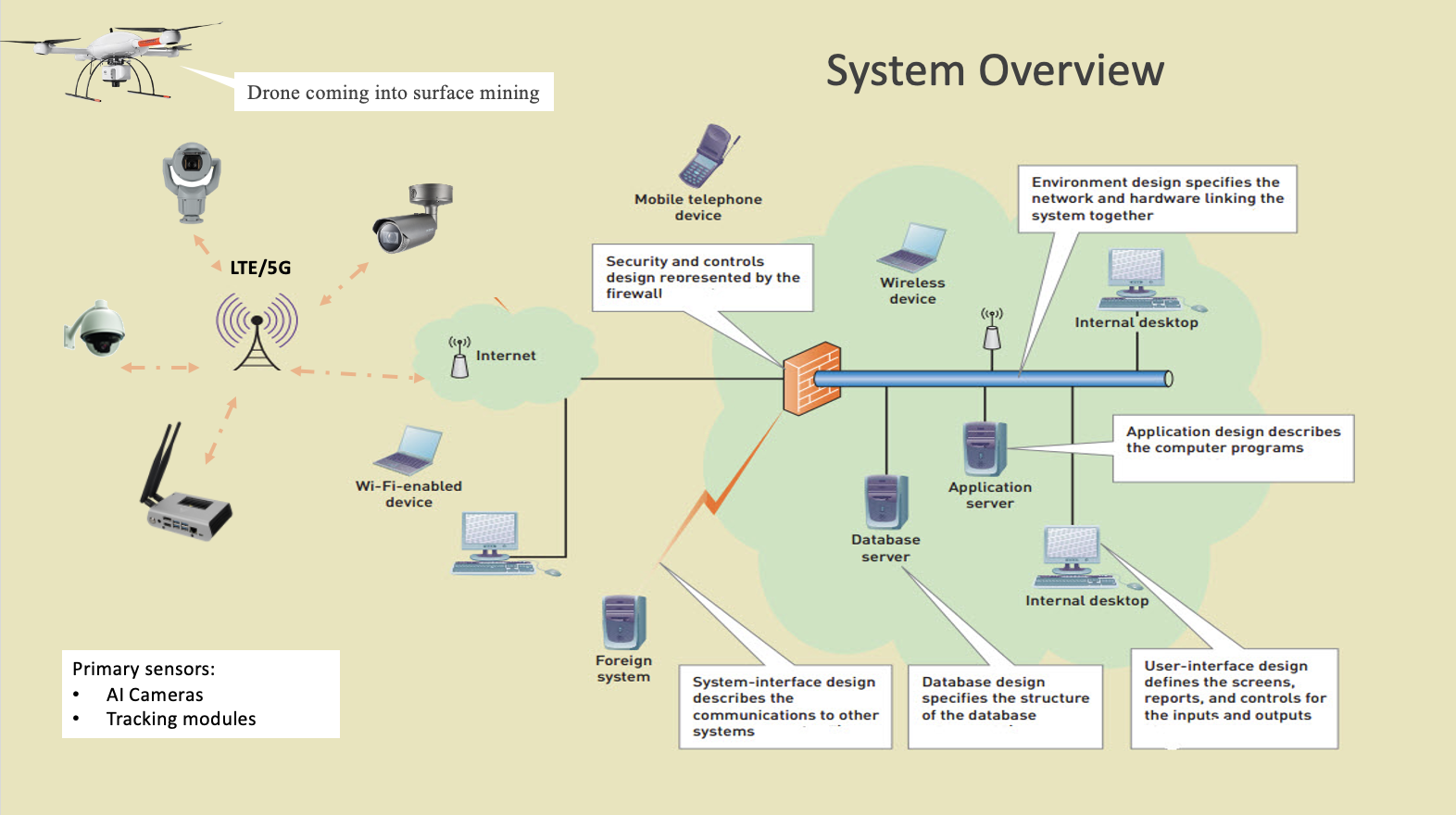

System Architecture

This system consists of cloud platform, HD video cameras and drones. They are connected via wireless technologies including 4G and 5G cellular communication networks.

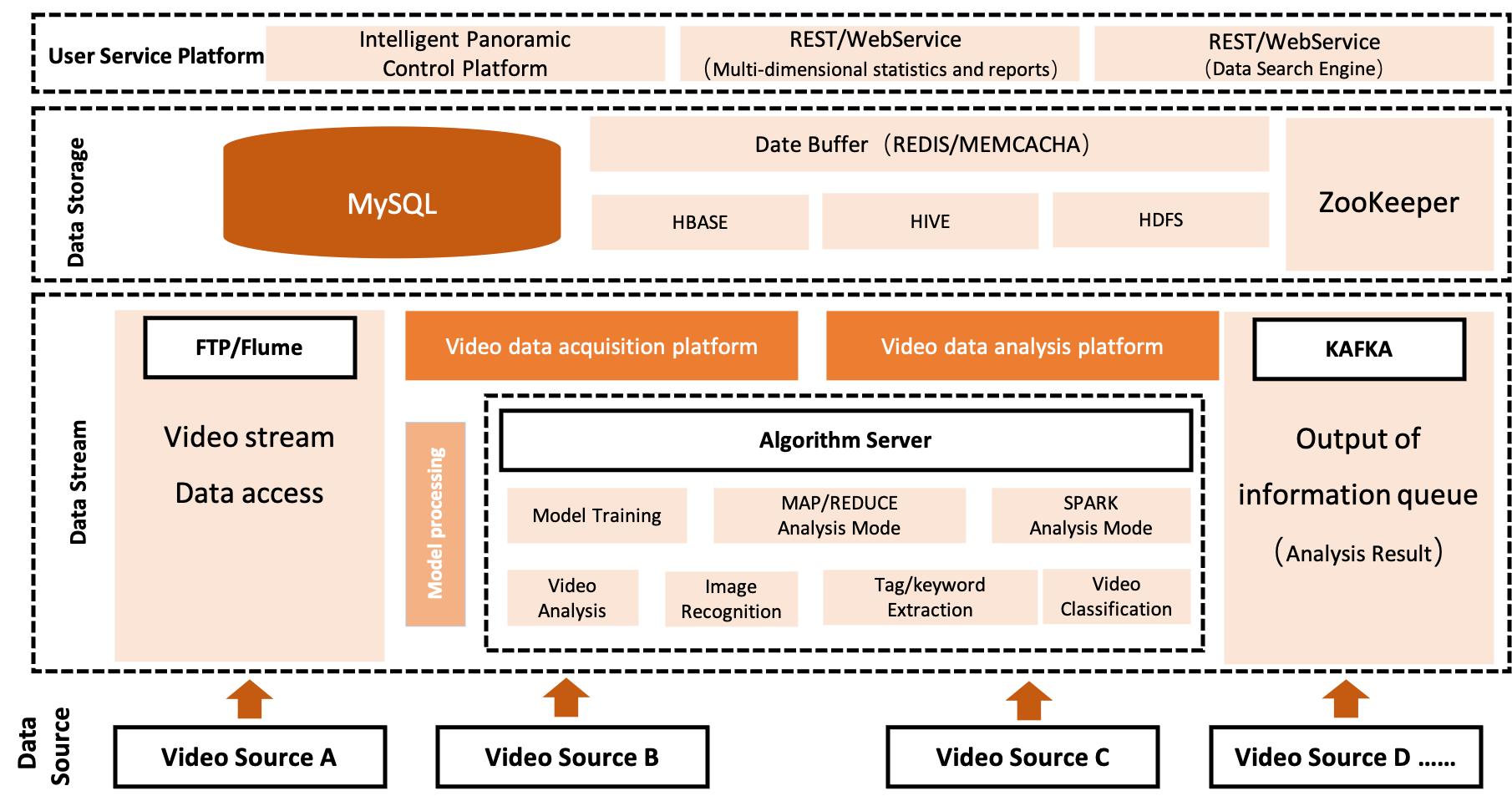

Platform Architecture

The cloud based platform connects and manages all the devices and is capable of collecting, analyzing and providing visual data reports for the decision-making.

Key Features

Based on the AI and ML technologies, our system can be able to provide lots of advance features:

- Smoke and fire early detection

- Helmet screening

- Traffic monitoring

- Truck loading screening

- Mineral inspection

- Fatigue monitoring

- Geofencing and wearables

- UAV for inspection

Application Scenarios

We help businesses of all sizes to increase visibility, drive more traffic and improve commercial success

Truck tracking and traffic monitoring

By detecting and tracking, the position and movement speed of each truck over period of time is calculated to determine whether the vehicle is waiting in line die to the on-site traffic jam.

Truck loading status

The cargo carrier and the cargo in it are segmented and identified to determine the type of cargo and debris (plastics, metals, etc.). Estimate the volume of cargo according to the compartment cover and the dividing line of the cargo and determine whether it is overloaded or underloaded.

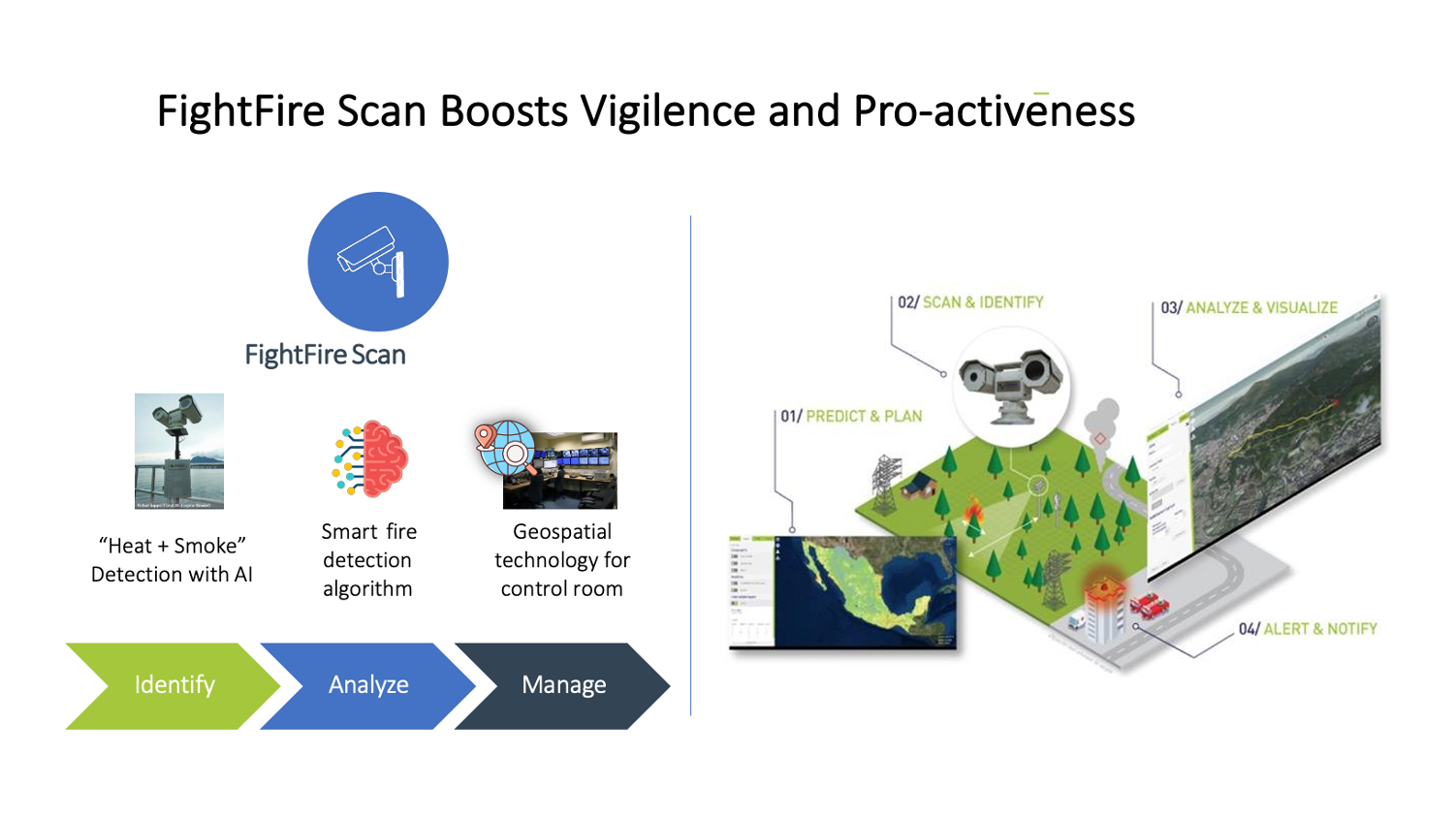

Smoke and fire early detection

The robots scan 360° 24/7 and are equipped with advanced LWIR and Electro-optical sensors that detect wildfires within minutes of ignition

Mineral inspection

Deep Learning AI technology is used to identify the contamination or debris (plastics, metals, etc.) in the minerals.

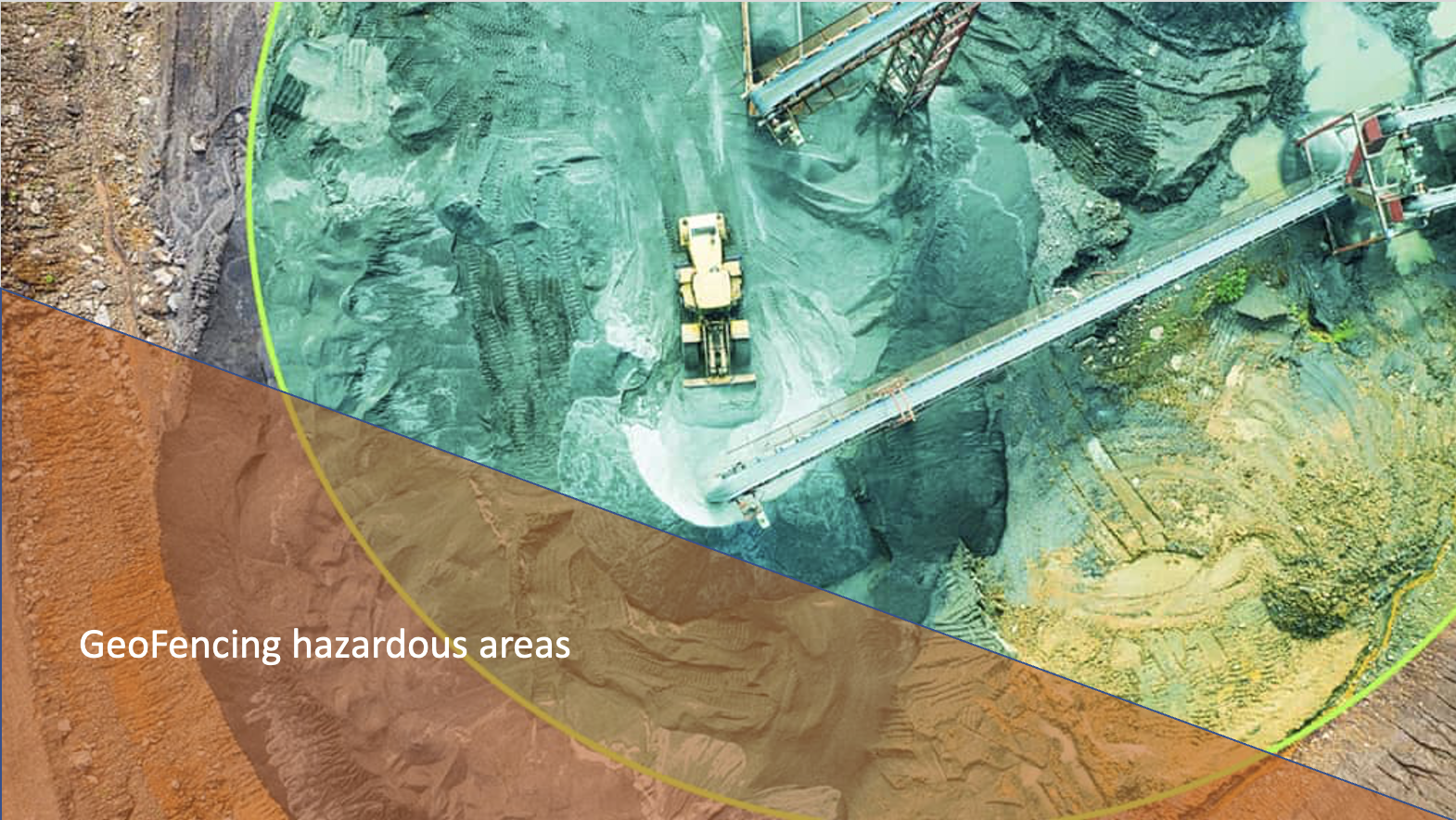

Geofencing and wearables

There are many hazardous areas at the mining site. GeoFencing can be relied on by employees as well as contractors to avoid prohibited areas.

UAV inspection

Aerial Vigilance – Using drone for routine operations, including efficient inspection, timely guideline for mine planning and safety, and on-site delivery.

Helmet Screening

Through various technologies , the engineering service is turned into a perceptible IoT control node, realizing regular self-checking and automatic alarming of engineering clothing, effectively monitoring the status of each set of engineering clothing, and timely discovering and dealing with personnel wearing problems and engineering services. Failure problems reduce the hidden dangers of construction site safety.

Fatigue Monitoring

Cameras in the driver’s cabin record the driver’s facial expressions, eye movements and head-turns, if signs of fatigue or drowsiness and abnormal behaviors are identified, an audible signal is emitted.