Smart Manufacturing

Industrial 4.0 is the Driving Force behind the Digital Transformation of Manufacturing. Smart manufacturing is the application of technology to digitally transform how manufacturing companies operate. It is driven by a need to boost efficiency, become more agile to respond to market unpredictability, improve quality, safety and compliance

Industry Trend

Smart manufacturing is the most current, highly beneficial result of technological advancements in recent years, and is becoming the focus of manufacturing globally. Smart manufacturing can accurately predict requirements, identify errors, as well as make innovation and the manufacturing process more manageable. It is the process of combining and implementing various technologies and solutions into the traditional manufacturing process, and it is also the process to reshape all manufacturing industries with digitization.

Xingtera’s Digital Manufacturing Solution Suite puts together state-of-art solutions powered by 5G, advanced industrial IOT, machine vision, automation and robots, AR technology and data analytics platforms—designed to help manufacturing companies to innovate its product and production process, and realize intelligent manufacturing. Our Smart Manufacturing systems will deliver high efficiency, improve quality, boost productivity, increase profit and enable new business models. The cloud based, End-to-End turnkey solution will simplify our customers’ digital transformation for sure.

What are Challenges in Today's Manufacturing

Manufacturing is an exciting industry, but like any other market sector, it faces its fair share of challenges. Manufacturing companies must overcome these hurdles and challenges to continue succeeding in 2021 and beyond.

Disruptive Technologies

Xingtera’s Smart Manufacturing solution has adopted the most advanced technologies in order to catch up with the trend of industrial 4.0 and help our customers to implement a revolutionary solution for their manufactories.

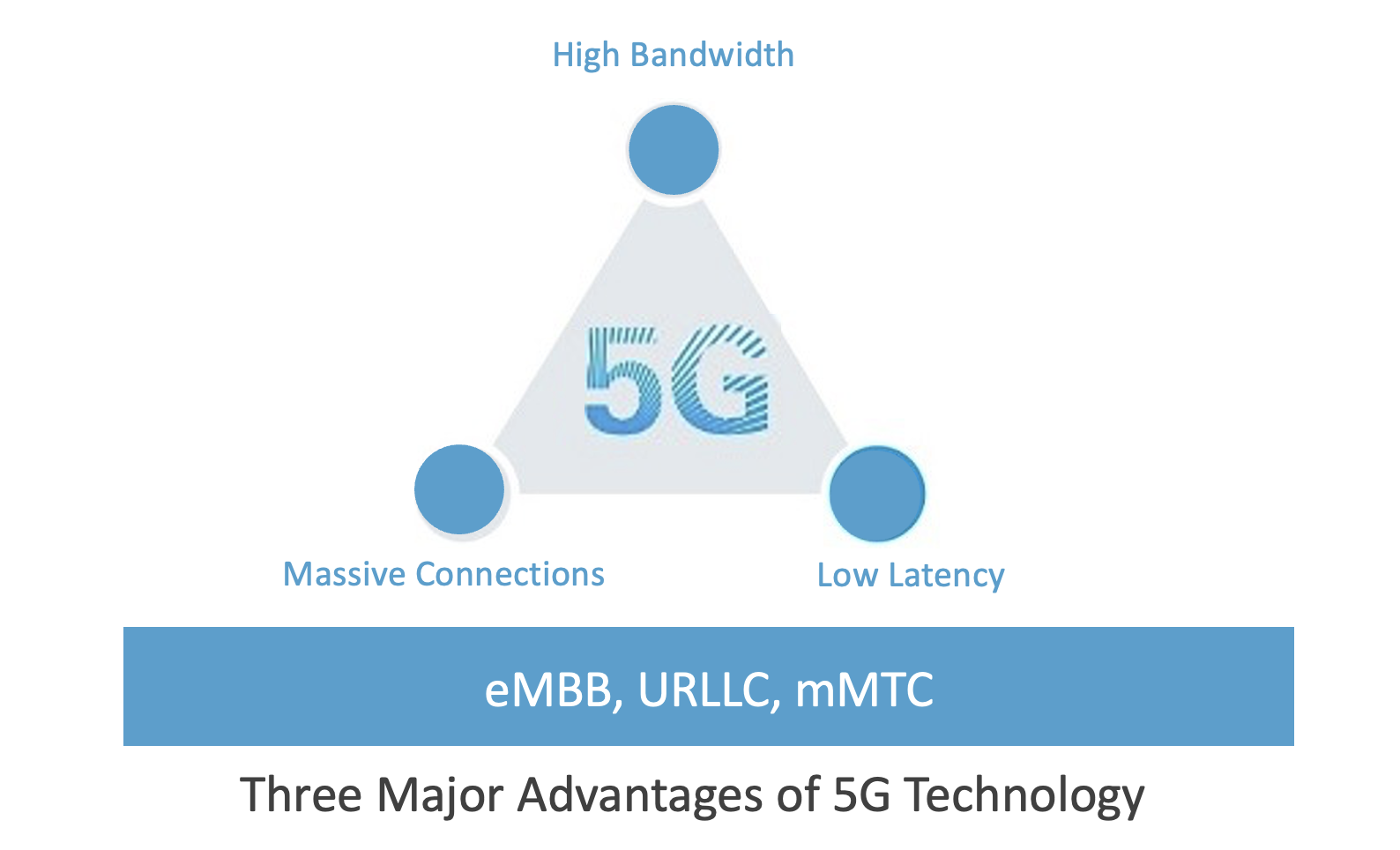

5G Private Cellular Network

If AI is the Brain behind Industrial 4.0, 5G is literally the Heart of Smart Manufacturing. Here is why:

Industry 4.0 makes use of highly automated, intelligent and collaborative cyber-physical systems which require highly stable, low-latency wireless connections, legacy fixed Ethernet won’t fit the changes and the limits of commercially-supplied Wi-Fi and LTE cellular networks can not perform due to its limits. 5G stands out because its high bandwidth, massive connections and ultra low latency. Transitioning to a private 5G wireless network offers flexibility to reconfigure, upgrade and evolve the setup as needed enabling factory operations to run smoothly and cost-effectively.

Machine Vision

Machine vision system automatically acquires and analyzes an image to deliver desired information and control machines or processes. It is the automatic extraction of information from digital images for process or quality control. In factories, there are lots of repetitive inspection tasks that requires human inspectors to fulfill. Machine Vision perfectly fits this kind of work. It is faster, more objective, and works continuously. Machine vision can inspect hundreds or even thousands of parts per minute and provides more consistent and reliable inspection results. As result, these systems replace incapability of human inspector to maintain a high level of error recognition for a long period.

Automation and Robots

With skilled labor harder to find and retain, many warehouses and manufacturing facilities are implementing automated robotic solutions into their operations. And with recent technological advances, it’s now possible to automate small batch runs and sensitive, difficult components once thought impossible or too costly to automate. Automated robots and robotic systems are designed to be integrated into your operations with a specific task in mind, and are tailored to meet the unique needs of your business. Here are six common applications for integrating automated robotic systems: 1) Robotic Welding; 2) Robotic Packaging; 3) Robotic Pick & Place; 4) Robotic Dispensing; 5) Robotic Cutting; 6) Robotic Non-Destructive Inspection

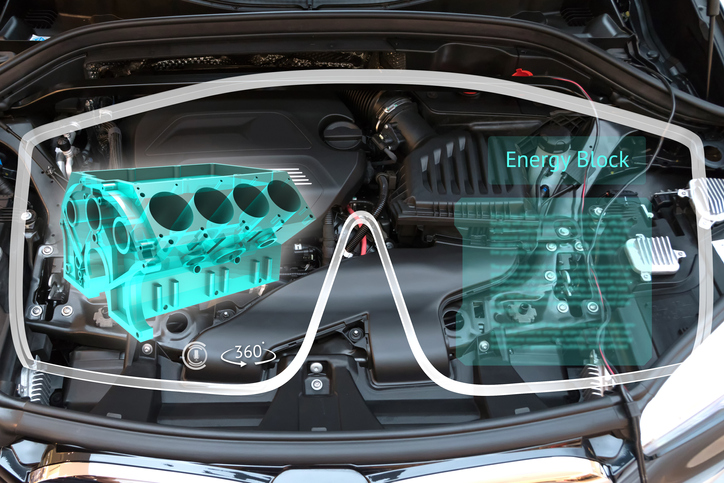

AR and VR Technologies

Virtual Reality (VR) technology creates a simulated three-dimensional environment that a user can perceive as real and provides an immersive experience in the artificial environment, whereas Augmented Reality (AR) increases the user experience in the real world by layering additional digital content and information onto the physical world as if it’s in your own space. In the era of Industry 4.0, the manufacturing industry is focusing on automation, Interconnectivity (IIoT), Machine Learning, and Artificial Intelligence to create new ways of operating. The use of AR/VR applications in manufacturing is is huge, especially in areas like product R&D, workplace design and layout, inventory management, remote maintenance and servicing of equipment, workers safety and real-time employee training and much more.

IoT Solutions

Smart manufacturing is the concept of leveraging data collected from many sensors and machine-to-machine communication to make informed decisions that help in optimizing production. IoT, using wired and non-wired connectivity, allows this data to flow freely. The data is collected and analyzed and then combined with contextual information, shared with the manufacturers. IoT gives them the capability to remotely monitor and manage processes and make the needed changes in real-time, and help them improve productivity, costs, quality and resource management. Therefore, the IoT has emerged as one of the core components of manufacturing transformation, ushering the world into the era of ‘smart manufacturing’.

Data Analytics

Data analytics is the science of analyzing raw data in order to make conclusions about that information. In factories, embedded sensors and connected production equipment, such as conveyors, fastening tools and robots, can provide manufacturing engineers and plant managers with reams of data. That information enables better and faster decision making within factories, and makes continuous improvements more quantified and disciplined. With advanced data analytics, manufacturers can capture and analyze data to gain meaningful insights into manufacturing challenges, take a deep dive into historical process data, identify patterns and relationships among discrete process steps and inputs, and then optimize the factors that prove to have the greatest effect on yield.

Key Features

Xingtera Smart Manufacturing solution suite is designed to develop a fully connected and flexible factory that can self-optimize its performance, learn and adapt to new demands, and become more and more intelligent.

- Pervasive Connectivities – Assets are fitted with smart sensors so systems can continuously pull data sets from both new and traditional sources, ensuring data are constantly updated and reflect current conditions.

- Optimized System – It allows operations to be executed with minimal manual intervention and high reliability.

- Transparency – Real-time data visualizations can transform various data captured in the field or in production and convert them into transparent and actionable insights, either for humans or autonomous decision making

- Proactive system – Employees and systems can anticipate and act before issues or challenges arise, rather than simply reacting to them after they occur.

- Agile flexibility – This feature and capability allows the smart factory to adapt to schedule and product changes with minimal intervention.

Application Scenarios

Xingtera is offering customized Smart Manufacturing solutions for different businesses scenarios.

Machine Vision Inspection

PCB flux defects may come in the form of corrosion and can cause harm to the assembly. Using real time machine vision can replace the human visual manual inspection and improve PCB production quality. 75%+ labor work can be removed.

Autonomous Mobile Robots

Autonomous Mobile Robots offer many benefits, such as liberating workers from loading and unload, low valuer and repetitive tasks, reducing error, re-work, and risk rates, and improving safety for employees in high-risk work environments.

Augmented Reality

Industrial AR helps to create and deliver easily consumable work instructions through a highly visual, interactive method of presenting relevant digital information in the context of the physical environment - connecting employees & improving business outcomes.

Pervasive IoTs

The pervasive adoptions of IoT in manufacturing enables the transition of tradition manufacturing systems into modern digitalized ones. It assists manage analytics and predictive maintenance.

Welding Robot

Robotic welding is highly productive for completing high-volume, repetitive tasks in your operations. Welding robots are both easy to program and able to help address the growing skills gap in the welding industry.

Application of Data Analytics

By combining airframe manufacturing data with artificial intelligence and machine learning, product managers can capture human variability and work content that reduces rework, disruption and downtime.